Industrial video surveillance system: what tasks it solves at Metinvest Group enterprises

Industrial video surveillance at Ukrainian metallurgical enterprises began with cumbersome "technical television" systems with limited functionality. Today, there are cameras that allow you to look even inside the oven with a temperature of up to a thousand degrees.

At the same time, industrial video surveillance is more than just cameras and monitors. It is a whole ecosystem with deeply integrated components: hardware, software, data storage and transmission services, intelligent analytics modules.

How Metinvest cameras help

The range of tasks for cameras has expanded. Today, one camera can be used to solve several problems. Among them are the following:

Control of technological processes and labor safety. Through a small but powerful camera lens, you can monitor technological processes and human safety. For example, how hot metal or cast iron is spilled, whether workers use flame retardant overalls or do not enter the danger zone.

In the rental shop, the cameras monitor the manufacturability of the process. The metal passes through the rollers, which give it the right shape, at high speed - about 5 meters per second. Sometimes it happens that the metal changes direction - tilts to the left or right. It is especially dangerous when it gets caught on the sides. Due to the high speed, the metal can demolish rolls, supports. This leads to production downtime, round-the-clock repairs, changes in the schedule of shipments. The video surveillance system allows the employee to see in time how the metal is being rolled and to react in case of a process violation.

Inbound and outbound cargo control. Thanks to the cameras, the operator can quickly check the compliance of the declared cargo and the filling of the car.

Cameras also record the output load. For example, how the metal is loaded into the railway car, how well it is packed, because in the future it can go a long distance. Therefore, the integrity of the packaging is important to maintain its quality.

In addition, the cameras help employees automate the measurement of cargo weight. It is no longer necessary to stop the train and weigh each car separately. This can be done dynamically. That is, during the movement of the train at a certain speed of weight automatically weigh a car. And the video surveillance system records the number of the car, recognizes it and enters it into the system in the form of symbols (not pictures). The process is automated, the employee no longer needs to manually rewrite car numbers and enter them into the system. Moreover, diesel fuel is saved due to the absence of the need for re-weighing.

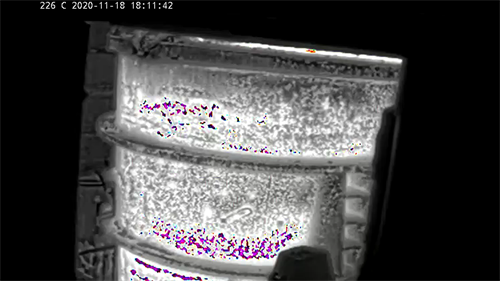

Temperature screening of the bucket lining, prevention of metal spillage. Special thermal imaging cameras can see even what is inaccessible to the human eye. For example, with the help of such equipment you can create a "thermal map" of the bucket lining.

The bucket is irreplaceable in oxygen-converter shop. To protect it from burnout (and it transports liquid metal with a temperature of more than a thousand degrees), a special lining is created from bricks.

The thermal imager camera helps to control the reliability of the lining. It is sent to the bucket and in a few minutes a heat map of different zones is obtained. Depending on the specific temperature, the area of the bucket is represented by different colors. If at some point the system detects an increase in temperature above the specified limits, the specialist will react quickly to prevent an emergency.

Monitoring of car cleaning. When loading the cargo, the camera can quickly detect the car that needs to be sent for further cleaning.

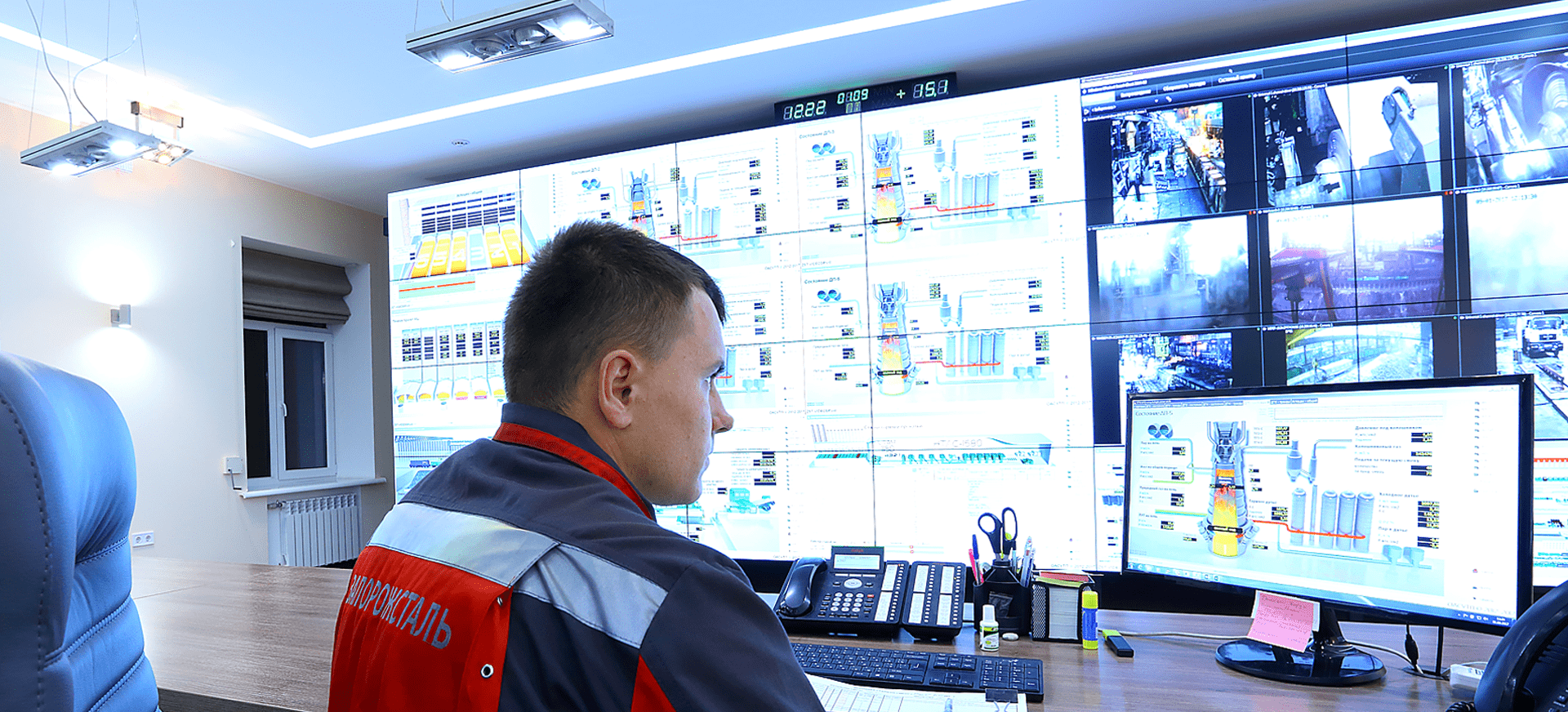

Construction of a centralized system Metinvest Digital has implemented and is developing a centralized video surveillance system on the Group's assets.

What are its advantages? First, the only standards that simplify administration and navigation. Second, flexibility in scaling. That is, you can add new cameras and assets, increase the number of system users quickly and without extra costs. Third, it allows you to see a single picture, as well as optimize development and maintenance costs.

Currently, the centralized video surveillance system covers eight enterprises of the group. Their number is constantly expanding.

Recording and control is performed using VMS Milestone Xprotect® - software for complex video surveillance systems with multiple objects and high requirements for information security. The software is complemented by advanced solutions that allow you to reduce traffic, file size on servers.

Today the system is more than 1,700 cameras, 29 servers, 350 TB of storage space. And it allows you to view in real time what is happening in a particular enterprise not only from a computer but also a mobile device. Developed functionality for two platforms (Android and IOS).

The plan is to develop not only system coverage, but also intelligent analytics systems that allow you to quickly process video and respond to the situation. After all, intelligent systems are the future.