Metinvest achieves blast-furnace efficiency with Azure Machine learning

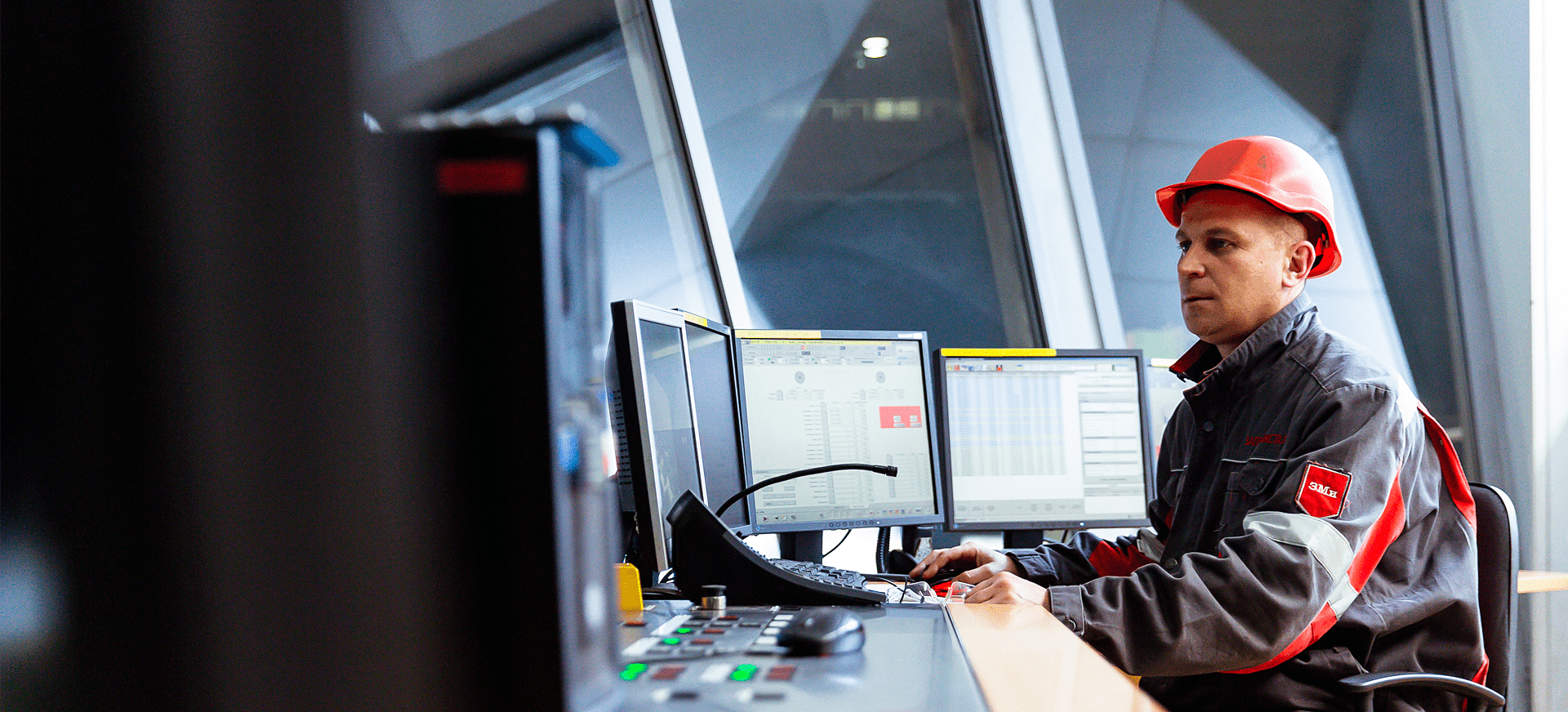

With a staff of over 80,000, Ukraine-headquartered Metinvest is a major name in end-to-end steel production. Looking to improve the efficiency of its blast furnaces — reducing fuel consumption by controlling the silicon content in its iron — the company started a pilot project with Azure Data Factory and Azure Machine Learning. Having seen its efficiency improve against benchmarks set by industry leaders, the company is now looking to roll out the solution across all its furnaces.

Metinvest is an international, vertically integrated group of steel and mining companies with a global sales network and manufacturing sites in Ukraine, Europe, and the United States. Metinvest manages the complete production chain, from extracting iron ore and coal to manufacturing semi-finished and finished steel products.

The need for more fuel-efficient blast furnaces

In late 2018, Metinvest launched a large-scale program aimed at improving the efficiency of its assets. “One major aspect was to improve the fuel consumption of the blast furnaces with the expected added value of over US$100 million,“ explains Kirill Makarov, Director of Continuous Improvement at Metinvest Holding. Indeed, the fuel consumption in a blast furnace varies depending on several factors, one of which is the silicon content in the cast iron with an indirect indicator of heating. The higher the silicon content in the cast iron, the higher the heating and fuel consumption. However, lowering the silicon content requires a fine balance, since, with a low silicon content, there is a risk of cold snap and disruption of the blast furnace. The accuracy of the assessment of the future thermal state of the blast furnace and the corresponding control actions are the key to stability. "Reducing the silicon content by 0.1 percent can allow us to save up to ten kilograms of coke. Thus, we need to stabilize the blast furnace process and reduce the variability of the silicon content in cast iron,” says Makarov.

To achieve this goal, Metinvest began an artificial intelligence pilot program in one of its blast furnaces—using machine learning to predict the silicon content in the iron over a time horizon of up to nine hours.

A successful pilot program rollout

“We use Azure Data Factory as the main orchestration tool in our data integration process. Data is being uploaded on a regular basis, and the model we developed in Azure Machine Learning predicts the amount of silicon in cast iron. After that, the Azure Machine Learning pipelines kick in. These pipelines help to retrieve data and launch the actual Python scripts including those responsible for data preparation. The machine learning models use this data to predict silicon content. The results of prediction are uploaded to the Azure SQL database,“ explains Alexandr Perkhun, Head of Data Management Department at Metinvest Digital. “On the front end, we have a Power BI dashboard, which is refreshed hourly. Users have access to the dashboard so they can adapt key indicators and operate the furnaces according to predictions. This helps ensure silicon is within the specified range,” explains Vladimir Kravchenko, Business Transformation Expert at Metinvest Holding.

The implementation was accompanied by complex measures: starting from the adaptation of the algorithms for controlling the thermal conditions of the blast furnace, training the operators of the blast furnace, and revising the goals and motivational component of the shop employees. It took three months to stabilize the thermal conditions and to reduce the silicon in the cast iron. As a result, by the end of the year, the silicon variability had decreased from the historical 0.16 to 0.1, which made it possible to reduce the silicon content in cast iron and obtain targeted coke savings. Metinvest now set its sights to roll out the fully developed solution across all its furnaces as soon as possible.

Accelerating data-driven process management

Metinvest is looking closely at all its production assets to experiment with other use cases for machine learning. “For us, it's only the start of this digital journey," enthuses Andrey Trach, Director of Business Process Transformation at Metinvest Holding. "We have the ambition to embed digital solutions along the whole value chain to bring significant operational improvements from the next level of data-driven process management.”

“Big Data is a new asset that generates additional business value, and we perceive it as one of our crucial business drivers. Hence, the complexity of analytics requires a strategic cloud roadmap that includes not only infrastructure development and creating a set of tools for efficient data processing but also supporting the culture for data-driven organizations. In line with our Cloud First strategy, Metinvest Group uses Azure services as an enabler for implementing digital initiatives. We use cutting-edge technology stacks like the one we see in the forecasting silicon content project. Moreover, we are moving forward to building corporate Data Lake and Data Warehouse based on Azure that helps us significantly improve the culture of Data Management within all manufacturing and business processes at Metinvest and maximize our operational efficiency,” summarizes Sergiy Detyuk, Chief Information Officer at Metinvest Holding, and CEO at Metinvest Digital.

*****

“Modern digital technologies hold significant potential for operational efficiency in the metals and mining industry. Predicting silicon content in the iron to control blast furnace heat balance is strong evidence of that”.

Olga Ovchinnikova, Economics and Business System Development Director

“Big Data is a new asset that generates additional business value, and we perceive it as one of our crucial business drivers. Hence, the complexity of analytics requires a strategic cloud roadmap that includes not only infrastructure development and creating a set of tools for efficient data processing, but also supporting the culture for the data-driven organization”.

Sergiy Detyuk, Chief Information Officer at Metinvest Holding, and CEO Metinvest Holding